The leading e-fuels company has selected Techint E&C to develop the engineering for its first large-scale e-fuels plant in Chile. The project marks a significant milestone for both companies and consolidates the country's position at the forefront of sustainable energy solutions.

HIF and Techint have joined forces to build a groundbreaking e-fuel plant in the country. This first-of-its-kind facility marks a major win for both companies, solidifying their position at the forefront of clean energy.

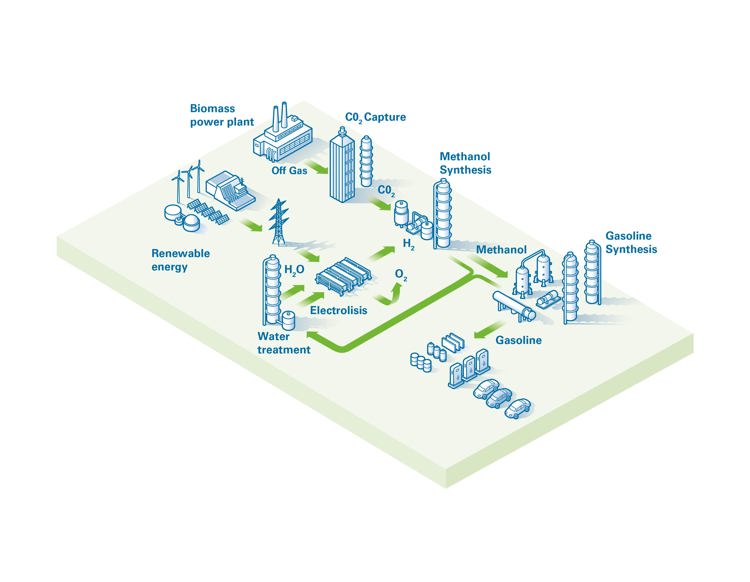

The center of this collaboration is the "Cabo Negro" plant, strategically located in Punta Arenas, in southern Chile. This will boast a relevant production capacity, churning up to 173,600 tons of e-methanol and 70,000 tons of e-gasoline annually. These clean fuels will be the lifeblood of a sector transitioning from fossil fuels. The entire production process will be powered by renewable energy from the soon-to-be-built Faro del Sur wind farm.

Claudio Perillo, President of Techint E&C's Andean Region, highlighted the project's transformative potential. "This project transcends the mere design of an e-fuels facility; it's a global turning point that positions Chile as a leader in sustainable energy," he remarked. "We are thrilled to support HIF on this journey by leveraging our global expertise, knowledge, and capabilities. Projects like Cabo Negro pave the way for Latin America's energy transition and validate our long-term strategy as a leading engineering and construction company."

The project is divided into three stages: the first stage, lasting two months, involves developing conceptual engineering to define the design of Hydrogen, Biomass, and Carbon Capture plants. Subsequently, a second basic engineering stage concludes in the fifth month by delivering a Class 3 CAPEX estimation. From that point until the project's completion at month 11, extended basic engineering will be conducted to achieve a Class 2 CAPEX estimation.

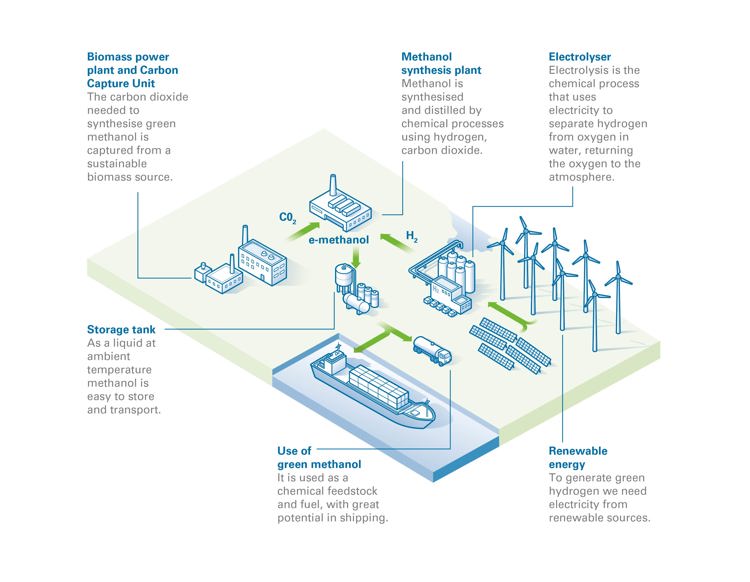

The heart of the project lies in the innovative e-fuel production process. Renewable energy sources power electrolyzers that separate hydrogen from water. This "green hydrogen" is combined with captured carbon dioxide to create carbon-neutral fuel. Functionally identical to conventional fuels, this clean alternative can be readily used in existing engines without modifications.

Victor Turpaud, HIF's regional manager for Latin America, expressed his company's enthusiasm for collaboration. "The success of Haru Oni, our pilot plant, has already demonstrated the viability of carbon-neutral fuels as a game-changer, paving the way for decarbonizing not just cars but also trucks, ships, and airplanes," he stated. "Now, we're scaling up production by joining forces with Techint E&C. Their extensive experience developing South American projects is invaluable as we strive to achieve our shared decarbonization goals."

"We're witnessing a growing trend in our markets," explained Hernán Milberg, senior manager of Energy Transition at Techint E&C. Companies driving energy transition initiatives increasingly require early-stage support from EPC firms with specific engineering expertise in green technologies and construction experience. This positions companies like us favorably as clients seek partners capable of navigating the complexities of these groundbreaking projects."

Building a plant that relies on an off-grid renewable energy source presents unique challenges. The wind's variable nature means the plant's production will constantly fluctuate. To address this, all process units will be meticulously designed to adapt quickly to these variations. Additionally, logistical hurdles exist due to the limitations of the port and surrounding roads. To minimize on-site work and mitigate the impact of harsh weather conditions, Techint E&C will conduct a constructability analysis of prefabricated modules early.

The engineering hours allocated for this project amount to approximately 100,000. An expected peak project team of 60 specialists from Techint's Engineering Centers worldwide (Buenos Aires, Argentina; Seville, Spain; Milan, Italy; and Mumbai, India) will tackle this innovative project, collaborating closely with HIF Global.